Digital Transformation of Manufacturing Industry towards Industry 5.0

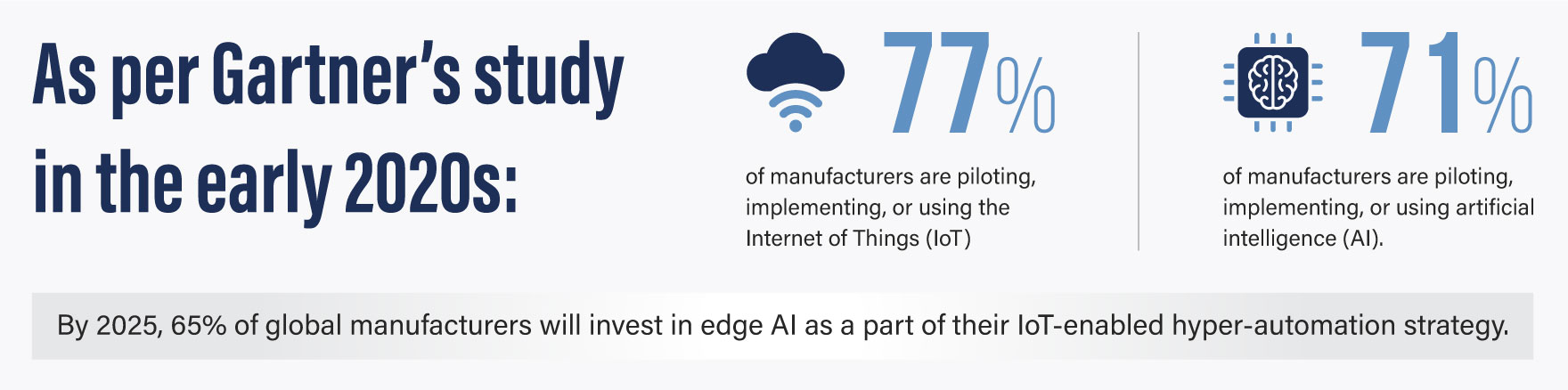

The manufacturing sector has either played a key role or led industrial revolutions that the global economy has witnessed. During industrial 4.0 manufacturing industry has increased its level of automation, with the evolution of robotics in the factory going from expensive, traditional, bolted-to-the-floor materials handling equipment to affordable, flexible, automated intralogistics smart robots (ISRs). This digital transformation in the manufacturing industry not only solves key business problems but also creates new opportunities. Internet of Things (IoT) edge solutions such as computer vision on production lines help with overall employee productivity through the immediate and real-time analysis of product quality. The emergence of digital transformation technologies like the Industrial Internet of Things (IIOT) and Generative Artificial Intelligence (GEN AI) have become synonymous with increased productivity and efficiency. Traditional factories with limited automation are becoming smart factories where humans are working alongside AI-driven bots. As per Gartner’s study in the early 2020s, 77% of manufacturers are piloting, implementing, or using the Internet of Things (IoT); 71% of manufacturers are piloting, implementing, or using artificial intelligence (AI). By 2025, 65% of global manufacturers will invest in edge AI as a part of their IoT-enabled hyper-automation strategy.

The manufacturing sector has always strived for efficiency during its evolution journey. To further improve efficiency and optimization companies are adopting industrial classification standards. Product content syndication-based solutions help organizations to streamline the intricate process of managing and disseminating product data. It facilitates the importing of product data from diverse sources and file formats, enabling manufacturers to optimize and customize the data to meet stringent standards.

Manufacturers of today are also looking for more and more ways to differentiate themselves from competitors. They are interested in providing ongoing services for customers, rather than simply selling products. This requires a shift to relevant processes and infrastructure in place for the new service-oriented business model. For example, servitization is transforming the traditional manufacturing business model. It has led to the need for delivering and selling services using e-commerce channels such as service portals which connect to services delivered with backend operations.

New trends like the e-commerce channel for sales which is connected and aligned with manufacturing operations, servitization, and product syndication are becoming the norm of manufacturing organizations.

The change in the nature of factories has led to governing bodies and institutions to push new-age ESG norms with sustainability taking center stage. In countries like India Securities and Exchange Board of India (SEBI) has mandated that the top 1,000 listed entities by market capitalization make disclosures about their ESG policies and practices.

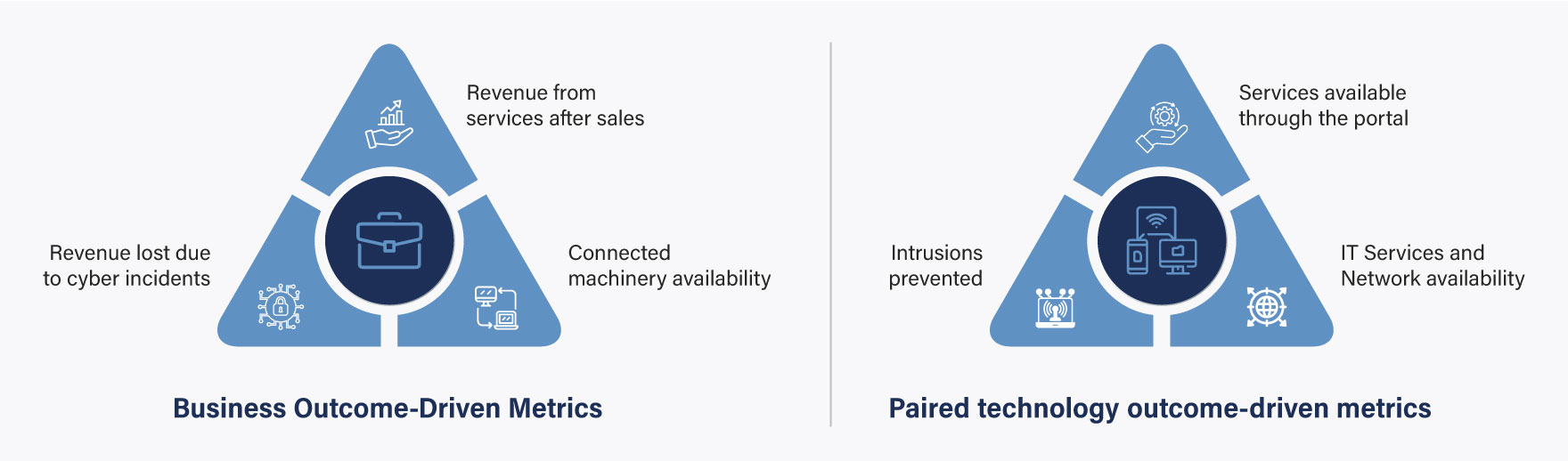

Such technological advancements require CXOs to invest in the latest digital transformation services. However, the CIOs struggle to measure and articulate the quantifiable value aspects of their technology investments. Often CIOs measure IT performance in terms that don’t resonate with executive stakeholders resulting in IT budgets being challenged and blocking the organization from achieving its technology-enabled objectives. CIOs need to create an explicit line of sight between IT performance and business outcomes and report business outcomes-driven metrics.

To manage and handle rapid and disruptive technological advancements to remain efficient and competitive, adopt and comply with newer standards and ESG directives enforced by regulatory and government institutions. The CXOs of the manufacturing industry need to choose their platform for enterprise service management carefully. It requires a new-age platform that assimilates the latest technologies and helps organizations manage, govern, and make data-driven decisions. ServiceNow has been an industry leader recognized in magic quadrants of Gartner which offers workflow and digital transformation solutions, helping organizations in Servitization, follow ESG directives, and comply with standards enforced by regulatory and government agencies. Features like unified service requests, service portals, integration with IoT devices, AI-driven predictive intelligence, workflow-driven management of Information Technology – Operational Technology, etc. make it a platform of choice. ServiceNow platform capabilities can enable manufacturing organizations to lead the journey of digital transformation toward industry 5.0.

Related Blogs

Generative AI in Telecom Industry for a Connected Future

Telephone companies (Telcos) have been struggling for years with insipid growth. Has the quest for catalysts to propel growth reached a tipping point amidst the rise of Generative AI in…

Myths and Truths about Digital Transformation

What is Digital Transformation? Is there one technology that fits all problems? The answer is ‘No’. Is it a quick fix for all Business Transformation solutions? The answer is still…

Tales around ROI of Employee Training Programs

Let us touch upon a topic that has been the bone of contention for Talent Leaders, Business Leaders, and Training practitioners, alike. Let us delve into the world of Training…